World’s Fastest High-Resolution

SWIR Cameras Now Available New FXO camera featuring

Sony IMX992 & Sony IMX993 SenSWIR sensors

with 5.2MP and 3.1MP including cooled option (TEC)

Samples with and without TEC available!

Advantages of SVS-Vistek SenSWIR cameras

The SenSWIR sensors used in the FXO SWIR cameras combine the robustness of a standard industrial camera with the advantages of SWIR technology. Due to their compactness and excellent image quality, FXO SWIR cameras are ideal for applications that require high resolutions and fast frame rates.

- High resolution of 5.2MP and 3.1MP

- New: TEC and TECless option

Thermoelectric cooling with ΔT = 30K cooling performance (sensor temperature range 15°C - 45°C) - Small 3.45 µm pixels enable to capture smallest details by using C-Mount lenses

- The high bandwidth 10GigE Vision or CoaXPress 12 interface enables sensors to be read out at the highest frame rates to speed up inspection processes

- Proven and reliable industrial camera design with integrated Strobe Controller and a compact housing of 50 x 50mm facilitates the system integration

- Extended wavelength range of 400-1700 nm enable to address a wide range of inspection tasks

- High quantum efficiency results in exceptional sensitivity

- First-class and homogeneous image quality, due to 2-point NUC and Defect Pixel Correction (DPC)

- GenICam-compatible features and transport layer simplify the software integration and use of third-party software

- Simultaneous inspection of VIS and SWIR from a single perspective simplifies assignments

Efficient and elegant inspection

Efficient and elegant inspection

Combine the potential of SWIR imaging with the simplicity and robustness of conventional image processing. Our FXO SWIR cameras enable efficient inspection and reliable quality control.

High-Resolution SWIR Imaging at fast frame rates

FXO SWIR cameras are operating the High-Resolution SenSWIR sensors IMX992 and IMX993 at highest frame rates. This is supported by standardized 10GigE Vision and CXP-12 interfaces, which enable reliable communication between camera and host. Thus, processes can be accelerated, and smallest details captured.

TEC option

Thermoelectric cooling, also known as TEC, uses the Peltier effect to transfer heat away from electronic components, especially sensors. By stabilizing the sensor temperature, the dark current is reduced, resulting in an improved and reproducible image quality.

One camera for SWIR and visible imaging

The camera's extended wavelength range, from 400 to 1700 nm, enables simultaneous recording of SWIR and visible images, eliminating the need for dual camera setups. No comparison of different viewing angles between SWIR and VIS images is necessary.

As simple as a GenICam industrial camera

The SenSWIR FXO series cameras are the ideal choice for industrial use, offering all necessary functions. Integration into new and existing applications is easy with the SVS-Vistek Toolkit and the GenTL interface, even when using third-party software.

Typical inspection solutions

Typical inspection solutions

with SWIR cameras

Imaging in the SWIR range offers many advantages, as materials can be identified due to their distinctive reflection properties or have specific absorption or transparency properties, which can be used to realize many imaging tasks that cannot be solved with conventional cameras for visible light.

Quality inspection of semiconductors such as solar-cells or ICs (e.g., flip-chip bonding, wafer alignment)

Content inspection of opaque containers, e.g. fill level

Water detection and localization (e.g. detect water/oil contamination and leaks)

Substance determination and detection of foreign substance contamination (e.g., pharmaceuticals, bulk goods)

Condition monitoring in agriculture and the food industry

Inspection and control of coatings (e.g., surface roughness, homogeneity, and thickness)

01 Detect moisture

Water shows prominent absorption bands in the SWIR range (e.g. at 1,450 nm). That’s why bruises on fruits and vegetables can be easily detected.

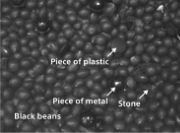

02 Detect foreign substances

Substances can display characteristic reflection spectra in the SWIR range, which can be utilized to confidently detect impurities.

03 Use SWIR transparency

Silicon-based materials and certain polymers are transparent in the SWIR range. This transparency is utilized for inspecting products like wafers or packaged ICs and for enabling inspection of opaque containers, e.g. in fill level inspection.

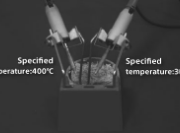

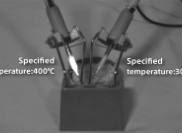

04 Measure temperatures

Hot objects with temperatures exceeding ~250°C emit high levels of SWIR radiation. This enables to measure temperatures or identify and inspect hot objects, such as weld seams or melts.

Our newest SWIR camera models

-

new

fxo992

- 10GigE or CXP-12

- 132 fps

- 5.2 MP

- C-Mount

- Integrated Multichannel Strobe Controller

- GenICam Interface & Transportlayer

- TEC and TECless options

- TEC Default Sensor Temperature 30°C

- TEC Temperature Range 15°C to 45°C

- TEC Cooling Performance ΔT = 30K

-

new

fxo993

- 10GigE or CXP-12

- 173.4 fps

- 3.1 MP

- C-Mount

- Integrated Multichannel Strobe Controller

- GenICam Interface & Transportlayer

- TEC and TECless options

- TEC Default Sensor Temperature 30°C

- TEC Temperature Range 15°C to 45°C

- TEC Cooling Performance ΔT = 30K

Contact us!

Our Machine Vision experts look forward to helping you find the perfect camera for your requirements.