Case Study Image processing for error-free label inspection

Do you have a similar requirement or questions?

Our experts will be happy to answer your questions and help you find the optimum system for you. ContactThese days, food production nearly always entails a high degree of automation. Among other things, Swiss company Kaiser engineering designs and assembles equipment used by renowned cheese producers. Automation and imaging components sourced from Fabrimex Systems AG, SVS-Vistek, Effilux and Matrox Imaging result in powerful systems permitting error-free food production all around the world.

“For us it’s all about automation” is the motto of Kaiser engineering in Rheinfelden near Basel. According to Roger Schweingruber, the deputy managing director of Kaiser engineering, the core skills of the company, which was established in 1972, can be divided into four segments: “In the area of mechanical engineering, we handle tasks such as engineering of special machinery and production equipment. Our second mainstay involves robotic solutions for a wide variety of different sectors. With our electrical engineering activities, we support our customers with all questions relating to project management for hardware and software as well as robot programming and programmable logic controllers. Our fourth area of business is devoted to machine vision technology.”

Roger Schweingruber explains that these four centers of competence can be used either individually or jointly: “In this way, we are able to supply an enormous range for all areas of industry. We engineer bespoke and optimized solutions for our customers from simple brackets to complex special machinery, prototypes and equipment.” He goes on to say that his company also customarily works on FDA-conformant designs for the food industry or GMP-conformant systems for the pharmaceuticals industry.

Reading cheese labels reliably

Kaiser engineering also leveraged its many years of experience in engineering food production equipment in a recent contract for a system that reads, checks and evaluates labels affixed to cheese packaging. The customer is a company well known in Switzerland as well as internationally that specializes in the production and distribution of dairy and cheese products.

“The labels on cheese packaging used to be checked solely for the presence of the barcode, while all the other information was ignored,” says Roger Schweingruber, explaining the situation that existed up until only a few months ago. “This was no longer acceptable for cheese producers especially as cheese packaging systems now operate at such high speeds that only an automated check is possible. Working closely with Fabrimex Systems AG, we developed a solution for this task which now achieves a reliable 100% check of all labels and all the data which they contain.”

Successful team work

Also based in Switzerland, Fabrimex Systems AG offers OEM and system solutions for automation and quality control in numerous sectors and has been working with Kaiser engineering for many years. This is how Roger Schweingruber explains the relationship: “Kaiser engineering supplies its customers with bespoke, turn-key systems assembled in accordance with its customers’ specifications. We source many of the automation components used in these systems from Fabrimex Systems, which recommend the optimum industrial PC systems, image processing components or measurement systems on the basis of the task at hand.”

Although he is able to utilize great image-processing experience from within his own company, Roger Schweingruber considers Fabrimex Systems to be the top experts in this field. “This partner has been advising us for years, supporting us in the selection of the optimum image processing components in light of the applicable requirements. In this respect, we rely completely on the recommendations we receive from Fabrimex Systems.” In this way, the team at Kaiser engineering subsequently integrates the machine vision components selected on this basis in the bespoke machinery and equipment. In addition, it programs the systems for its customers, frequently drawing on the experience that it has in robotics.

For many years, Fabrimex Systems has been the Swiss agent for the industrial cameras produced by the German company SVS-Vistek from Seefeld near Munich. What Thomas Graf, sales manager at Fabrimex Systems, particularly likes about the SVS-Vistek cameras is the broad range and high flexibility, among other things: “SVS-Vistek develops and produces high-quality cameras and is able to respond very quickly and flexibly to special customer requirements. The camera models and ranges that are available are extremely versatile in terms of their resolution, speed, interfaces and many other technical characteristics. For this reason, we have had very good experience with SVS-Vistek cameras with numerous installations for our customers over the last few years.”

Optimally configured image processing

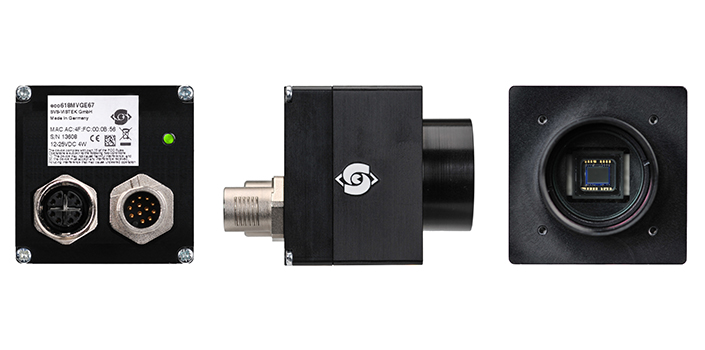

In the case of the systems for checking the labels on packaged cheese portions, Thomas Graf worked closely with Kaiser engineering to develop a machine vision system based on IP67-protected ECO 625 and ECO 815 GigE-Vision cameras with a resolution of 5 and 9 megapixels, respectively. They are fitted with the proven 2/3” and 1” Sony sensors. Depending on the requirements, the 12-megapixel version of this camera series is also used.

One of the special features of this range of cameras is the integrated two or four-channel flash controller, which can be operated directly via the camera. “This particular feature of the SVS-Vistek cameras has an advantage for users in that considerable time, space and money can be saved in integrating the system. Moreover, it is only necessary to use and synchronize a single SDK instead of two. This reduces resource requirements considerably,” explains Thomas Graf. Roger Schweingruber confirms this: “The resources and costs required to integrate these cameras in the system and the evaluation software were substantially lower than what we would normally expect. This is materially due to the SVS-Vistek cameras’ I/O design and integrated flash controllers.”

A further feature of the SVS-Vistek cameras also resulted in simpler and swifter engineering of the overall system according to Thomas Graf: “These cameras support the safe-trigger system in which the trigger signal is shielded from any disruptions.”

For Thomas Graf, a further argument in favor of the SVS-Vistek cameras is the dust- and water-proof UP67 body of the cameras. This means that they can be used in food production applications without any further protective casing. The production and processing systems used in this industry must be regularly cleaned, using high-pressure water jets in some cases. With the IP67 characteristics of both the tube and the camera body, the SVS-Vistek ECO cameras are able to withstand these tough requirements. The M8/M12 connection design, which is compliant with the field cabling standard, ensures the necessary impermeability in such applications. “The combination of these characteristics makes the ECO cameras the prime choice for Kaiser engineering,” says Thomas Graf.

Numerous different labels

As the packaging and labels tend to reflect the light generated by the flash in view of the nature of the materials used, thus rendering the ensuing evaluation more difficult, Kaiser engineering developed a tunnel-like indirect lighting unit specially optimized for this task and based on two LED lamps sourced from Effilux. The images gained in this way can be effortlessly evaluated using Matrox Design Assistant 5, which is based on the Matrox MIK imaging software. The entire image evaluation process is handled by a powerful fan-free industrial PC developed by Fabrimex Systems.

“This system handles around 150 different label types. Depending on the type of cheese and the customer, the labels may contain different data. Accordingly, a database linked to the imaging system initially only provides information on the data that is to be checked and read on the label in question,” explains Roger Schweingruber. “The data on each label is then transferred to the SAP system and stored.”

Roger Schweingruber mentions a further special feature of this system: “Each customer can individually decide which data is to be printed on the label. This means that we must design the imaging systems to be as flexible as possible, e.g. to permit non-alphanumerical evaluation as well.” He cites the inclusion of weights in American units or the use of the Cyrillic alphabet for the Russian market as examples of this. “We achieve this by using Matrox Imaging’s parameterizable image software Design Assistant 5, which possesses integrated recipe management in addition to many powerful imaging functions.”

The requirements for image processing are demanding: With a band speed of around 1 meter per second, there is only a maximum of 150 ms to read and evaluate two codes and to perform up to 20 additional checks of texts, date, logos or dimensions on each package. Roger Schweingruber explains that possible errors include missing or incorrect labels on the packaging or illegible, omitted or incorrectly evaluated labels. “Currently, the line is halted as soon as five errors are detected so that a manual check can be performed. However, looking forward, we want to completely automate this step as well,” explains Roger Schweingruber.

Plans for the future

According to Roger Schweingruber, four machines of the type described are being used by this cheese producer and operating very stably. In addition, Kaiser engineering is working on a further project involving the use of an extremely high-resolution SVS-Vistek camera with 47 megapixels. However, he prefers not to disclose the task for which this system is to be used at this stage.

Further information:

Domiciled in Switzerland for the past 30 years, Fabrimex Systems AG offers comprehensive services and a wide range of out-of-the-box and bespoke products in the areas of industrial PCs and embedded computer, machine vision and measurement recording which can be used to implement swift and cost-efficient solutions in a wide range of different applications.

Fabrimex Systems AG

Industriestr. 4B, Volketswil

Postfach

CH-8603 Schwerzenbach

Phone +41 44 908 13 60

Fax +41 44 908 13 67

Kaiser engineering GmbH was established as a sole proprietorship in 1972 and converted into a limited-liability company in 2005. It is one of the leading providers of special machinery in Switzerland.

Kaiser engineering GmbH

Theodorshofweg 22

CH-4310 Rheinfelden

Phone +41 61 845 91 91

Fax +41 61 845 91 90