Early detection is crucial in quickly and effectively combating forest fires. In case of danger, drones from Evolonic, equipped with an industrial camera and a lens from SVS-Vistek, provide firefighters with a valuable time advantage.

Braille is enormously important for people with visual impairments, especially when identifying medicines. With the DotScan inspection system based on industrial cameras and lenses from SVS-Vistek, in-situ ensures error-free Braille on pharmaceutical packaging.

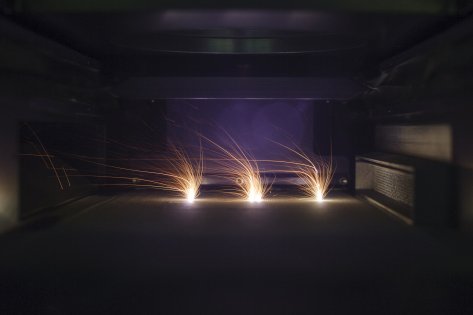

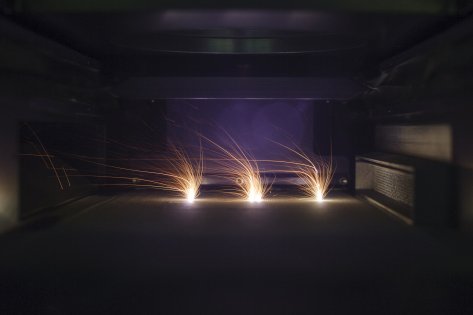

The goal of Aconity3D GmbH is to optimize the stability of an innovative manufacturing method called Powder Bed Laser Melting and to promote its use in a wide range of industries. By utilizing high-speed industrial cameras from SVS-Vistek, the company has come one step closer to this goal.

Automated inspection stations from Ziemann & Urban, equipped with industrial cameras from SVS-Vistek and other image processing components, enable pipette tip manufacturers to inspect pipette tips with high precision and at the same time economically.

Vision On Line´s Resident 1200 Visual Inspection machine vision system and industrial cameras from SVS-Vistek guarantee the fully automated 100% inspection of products at a leading manufacturer of complete turbocharger assemblies for cars and commercial vehicles.

New code reading solutions from Strelen Control Systems realize the sophisticated evaluation of tiny codes within very large fields of view using high-resolution cameras from SVS-Vistek with up to 151 megapixels.

The automated WEControlDOME incoming goods station from CompControl enables companies in the electronics manufacturing industry to record incoming containers with absolute transparency.

The goal of the Swiss company Asyril is to improve the performance of assembly robots. It uses sophisticated image processing systems to facilitate the gripping of bulk material components by robots in production, relying on an innovative idea and on industrial cameras from SVS-Vistek.

These days, food production nearly always entails a high degree of automation. Among other things, Swiss company Kaiser engineering designs and assembles equipment used by renowned cheese producers. Automation and imaging components sourced from Fabrimex Systems AG, SVS-Vistek, Effilux and Matrox Imaging result in powerful systems permitting error-free food production all around the world.

Up to 30 electrical plug-in connectors per second, each of which entail any number of adjustable test features, and each error has to be detected with 100% assurance. Based in Jena, Germany, OTTO Vision Technology GmbH builds testing systems that meet such high-end demands. In doing so, it relies on machine vision cameras provided by SVS-VISTEK GmbH.