Knowledgebase Tap Balancing on CCD sensors

To understand the complexity of tap balancing we need to go to the fundamentals of CCD imaging on the sensor itself. This document will explain the pros and cons of taps, along with some basic knowledge of CCD sensors.

Tap Balancing as a

Quality Criterion

In machine vision CCD sensor sizes are growing to 40 Megapixels and more. Big sensors are divided into sections ("taps") to speed up the readout. Tap Balancing is making sure sensor and image characeristics is the same for all these taps, without difference between these taps. The final image should look homogenous in terms of colour, black point, brightness and gamma. Tap Balancing is the algorithm doing exactly this job. The more taps a sensor is providing, the more challenging this task.

General principle of CCD tap readout

Single pixel

In a CCD sensor each pixel is represented by a MOS capacitor doing the conversion of incoming photons to voltage. While being exposed to light, electrons are summing up to a charge pool until the readout will empty the pool. The amount of electrons in the pool is correlating with the amount of light during exposure time.

This as a basis, generating a single pixel image works as follows:

- Light is generating a charge pool of electrons in a CCD cell. The resulting current is very weak

- So when reading out the cell’s voltage, the current has to be amplified

- Finally digitize the amplified, still analogue signal with an Analog-Digital-Converter to digital values

So we need an amplifier and an ADC to read a pixel. As soon the signal is digital, the digital output can be transferred lossless to any destination.

Lots of pixels

A CCD imaging device is consisting of lots of pixels. For knowing the whole image, these pixels have to be read – all of them, one after the other, cell after cell, line after line. All of them have to be amplified by our amplifier and then put digital by the ADC. This is a sequential thing: The next pixel can be read only if the one before has been read. With CCD sensors having 5, 10, maybe even 50 mega-pixels this reading process is consuming a lot of time - and a lot of work for our amplifier and ADC. The more data there is the less frames per second can be read.

Taps

The solution to the speed problem of readout is to split up the CCD array into several regions (“taps”) which can be read out in parallel. So reading a 4-tap sensor will take only a quarter of the single-tap readout time.

The only disadvantage of this approach: we need 4 amplifiers and 4 ADCs to read a 4-tap sensor. But this can be managed. So we’re speeding up with lots of taps?

The dark side

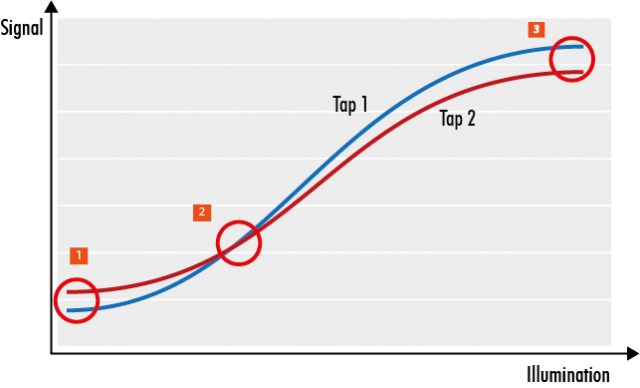

In an ideal world, all cells are similar, all amplifiers and all ADCs (Analog to Digital Converter) work the same way. Unfortunately cameras have to operate in the real world. Here we find that ADCs and amplifiers do differ in linearity and working points. These differences are leading to differing pixel values, different for each tap. These differences are visible. This might change for the worse due to fluctuating environment temperatures.

Linearity issues

With changing linearity of ADC or amplifier, the output from a CCD cell source will change without any changes in light. Blacks might change, brightness might be different.

Even darker

There is one more thing to mention. For reducing noise, amplifier or ADC have a black cut-off point. In low light conditions it might happen that one readout line (amplifier + ADC) is defining black with a different value than the other readout line. Result of bad tap balancing might look quite obvious with images on low light conditions close to the color black - and will be amplified by addig Gain to the amplifier, which is standard on low light conditions.

Tap Balancing as a solution

There is no way to the ideal world, but there are 3 approaches:

- Choose components for ADC and amplifier with care and minimum tolerances (expensive)

- Provide the possibility to optimize the default adjustments for a specific temperature (you have to know the operating conditions though, this might limit the temperature range of your application)

- When operating, try to keep linearity and black point by readjusting the amplifiers and ADCs according the measured temperature on the fly

Trying to catch up with small changes while running the CCD readout process is a sensitive task. Linearity and black levels might change and have to be adjusted - fast enough to compensate for temperature changes and slow enough to make changes in amplification not noticeable regarding image sequences.

The more taps you have to adjust, the more complex this taks is going to be without encountering an overall loss of dynamic range in the image.

The SVS-Vistek way with Industrial Cameras

For the customer's benefit, SVS- Vistek decided to provide all of these options. Image quality is a core business and lots of engineering efforts are put into tap balancing. By using high precision components the linearities already are excellent. All industrial cameras provide a measured preadjusted factory tap balancing. Depending on the sensor it comes together with a highly sophisticated algorithm for permanent on-the-fly readjustments. This algorithm is permanently monitoring the camera’s working conditions and is permanently readjusting the amplifiers. In this domain SVS-Vistek has worldwide reputation regarding the precision and smoothness of tap balancing.

This knowledge is fundamental for today’s large sensors with 25 MP and more, with CCD sensors of up to 16 taps.

So, SVS-Vistek multitap industrial cameras for machine vision provide following tap balancing possibilities (depending on sensor):

- Manual tap balancing

Manual readjustment is supported with with multitap CCD sensors - Auto mode

On auto mode the algorithm continuously compares taps and adjusts the parameters for every following image - One push mode

Readjust taps on homogenous sensor views like plane unfocused gray. You might use this if you want to get perfect balance in a specific gray area or temperature range. Does make sense only in 10 or 12 bit mode - Single tap readout

use only one ADC and amplifier for avoiding any tap issues at all. Avoid any tap balance issues for the price of speed

(See individual camera data sheets for included features.)