Shading with CMOS cameras

There are many good reasons for lens testing. But although an (expensive) lens has excellent values, it doesn't necessarily have to be compatible with your favorite camera. A shading effect can often be observed, but it is avoidable. Modern, high-resolution cameras with large CMOS sensors are particularly affected. A search for the cause.

Every lens causes shading

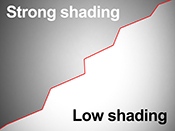

Shading is a well-known problem in optics. To put it briefly: The farther a pixel on the sensor is located from the optical axis, the darker the pixel is imaged. The image therefore becomes darker towards the edges. The phenomenon is point-symmetrical around the optical axis. Closing the aperture increases the usable image area. This kind of shading is well known to us and is continuously being improved by lens manufacturers.

Shading caused by the camera

The surprise often arises when a modern CMOS industrial camera is used, such as the high-resolution hr342 from SVS-Vistek with a Sony IMX342 sensor or cameras with a Canon 120MXSM sensor. With these high-quality CMOS cameras in combination with good optics, a shading effect can suddenly become visible that is demonstrably not available with less advanced camera. So what is the cause and how can this be avoided?

Cause CRA

A CMOS pixel (viewed from the light incidence side) consists of a light-sensitive area and a (light-insensitive) amplifier area. Modern CMOS sensors have so-called microlenses. A micro lens is placed above each individual CMOS cell, which directs the incident light onto the light sensitive part oft the pixel (and not the surrounding amplifier/electronics). This construction significantly increases the sensitivity of the pixel and reduces pixel noise caused by the object structure.

However, these advantages come at a price: The use of microlenses means that the incident light has to come from a certain angular range. Light incident outside this angular range (chief ray angle or CRA) is then directed more to the light-insensitive areas of the pixel - a clear reduction in intensity and thus a shading effect on this pixel is the result.

CRA and lens match

The incidence of light is perpendicular to the sensor on the lens axis. Most sensors have arranged the microlenses in such a way that the light incident should be optimally vertically. However, the further the individual pixel is located outside the lens axis towards the edge of the sensor, the more oblique the light enters with entocentric lenses. If this angle of incidence is greater than the CRA of the sensor, then shading is caused by the sensor.

By the way, telecentric lenses do not have this disadvantage: sensor-side (!) Telecentric lenses have a beam path perpendicular to the sensor on the entire sensor surface. MFT lenses (Micro Four Thirds) are almost all telecentric on the sensor side. There are however also CMOS sensors with a so-called pixel shift: Here the micro lenses are arranged in such a way that the positional offset of the micro lens image is compensated by a modified position of the micro lenses at the edge. However, telecentric lenses do not work for these sensors. For these sensors, however, telecentric lenses will not work.

Obviously, it is essential to harmonize lens and sensor in order to minimize the loss of dynamics in the image associated with shading correction.

Advice saves you own tests

Since CRA and the beam path on the sensor side do not depend on the focal length but on the design of the lens, special care must be taken when selecting lenses for such sensors with small or inhomogeneous CRA. The sensor-side beam path is a constructive feature and not a qualitative one, depending primarily on the position and size of the exit pupil. There are good reasons for every design, even lenses of the same focal length from the same manufacturer can be very different here.

SVS-Vistek has included the lens in advising camera solutions for decades. We would be happy to work with you to select the right lens for your camera.