Reassurance for logistics in the electronics industry

With the camera-based solution WEControlDOME, CompControl simplifies the registration of incoming goods in the electronics industry. The image processing for this automated goods receiving station, including an adapter for controlling the lenses used directly from the camera, comes from SVS-Vistek.

Everything has to be effective and precise when companies in the electronics industry receive new deliveries in goods receipt. Only if the incoming goods can be checked with as little time as possible, product quantities and types can be booked into the merchandise management system and then stored in a suitable place, can subsequent processing of the components be realized without further delays. Manual registration of incoming containers is usually too slow and too error-prone for this, making economical processes in this area almost impossible. However, automated solutions are usually not flexible enough to reliably identify the required data on the different geometric container formats of the incoming electronic components.

CompControl IT-Service und Vertriebs GmbH, based in Gersfeld, Germany, solves this problem with its automated goods receiving station WEControlDOME. “We developed this system especially for electronics manufacturing to enable companies from this industry to record incoming goods from containers at an incoming goods station in an absolutely transparent manner”, explains CompControl Managing Director Christoph Limpert.

WEControlDOME determines data such as the order item, the article type, the quantity, batch numbers and all other information through a barcode and plain text analysis and verifies the recorded data by comparing it with the manufacturer information. Without further manual intervention, the system also takes over the automatic goods receipt posting in the merchandise management or ERP system and allows the integration of an automatic labeling system for the containers as well as their photographic documentation.

Christoph Limpert, CompControl Managing Director (© CompControl GmbH)

31,4 megapixels capture all details

According to Limpert, the unique feature of this system is the automatic capture of each individual container and the barcode and plain text information on it via an integrated camera, which, through the use of an additional autofocus system, delivers images of sufficient quality even with objects of different heights. Such a system was necessary because the working distance for each image capture can differ from the previous data acquisition due to the different heights of the incoming packages. “This situation required a special setup of the image processing system, which we were able to realize with the help of SVS-Vistek”, says Limpert.

After initial preliminary talks with CompControl, the experts from SVS-Vistek quickly found the camera optimally suited for this application in their wide product portfolio: the monochrome GigE camera exo342MGE, with its high resolution of 31.4 megapixels, met all the requirements for capturing the barcode and plain text information on the component containers reliably and in sufficient quality, as well as transferring the image data to the connected PC for evaluation and storage. Proven features such as the excellent thermal concept, which allows operating temperatures of up to 60 °C, and the integrated, versatile light control were further reasons for using the exo342MGE to solve the task at CompControl.

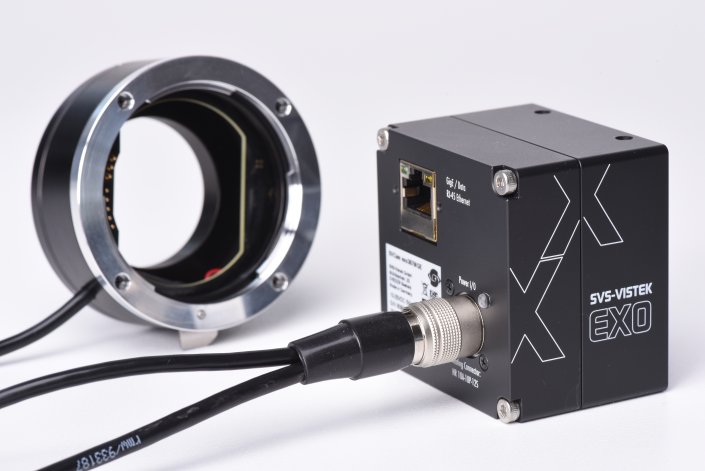

The main challenge, however, was to capture the images with the same quality despite the different heights of the test objects without having to intervene manually. SVS-Vistek solved this task with its SVS-EF adapter, a proprietary development of the company that allows convenient focus and aperture control of Canon EF-mount lenses directly from the camera. The SVS-EF adapter enables the camera to have an autofocus function and thus creates the conditions for flexible, fast and easy image acquisition of incoming electronic containers regardless of their height.

Trend towards small batch sizes

According to Thorsten Schmidt, Head of Product Management & Support at SVS-Vistek, the application of the SVS-EF adapter at CompControl represents a typical example of the function of this product: “In many industrial inspection solutions, fixed focal length lenses are still used. This makes sense in production lines where large quantities of one and the same part are manufactured and inspected over long periods of time. However, a completely different situation arises when inspecting parts with smaller quantities and frequently changing test objects: In these cases, an inspection solution must be quickly adapted to new products and parameters in order to ensure effective production.”

According to Schmidt, at least since the introduction of Industry 4.0, the trend has been moving in this direction: “If, in extreme cases, the batch size drops to a quantity of 1, more flexible solutions are an indispensable prerequisite for the economic success of production companies. Focusable lenses are an important building block here, as they facilitate the inspection of objects with different geometric dimensions.”

The SVS-EF adapter can be used in combination with numerous industrial cameras of the EXO, FXO and HR series from SVS-Vistek to control focusable lenses with Canon EF or EF-S mount without additional hardware and software. The camera controls and supplies power to the lens, which is seamlessly integrated into the camera's GenICam tree from a software perspective. The EF adapter is available in different variants for lens mounts with C-mount, M42 and M58 and can be used with all cameras of the EXO, FXO and HR series from SVS-Vistek. “Users have a wide choice of camera models from our portfolio in terms of resolution, image acquisition speed and interface to optimally design their image processing system according to the requirements of the application to be solved and to easily implement flexible inspection solutions”, Schmidt emphasizes.

Thorsten Schmidt, Chief Product Officer (CPO) - SVS-Vistek (© SVS-Vistek GmbH)

Proven solution

According to Managing Director Limpert, the WEControlDOME automated goods receiving stations from CompControl are already in use in large numbers and worldwide at many companies in the electronics industry. “After commissioning, these systems sometimes run in 3-shift operation around the clock at our customers and have proven to be very, very reliable there. In the rare cases of error, SVS-Vistek has always supported us quickly and solved image processing-based problems immediately. The good cooperation, that was already evident in the selection of components and the detailed feasibility studies during the development phase of the system, has also proven itself in the successful use of the goods-in stations.” According to Limpert, there is reason enough to continue the partnership that has existed for more than a decade and also to rely on image processing from SVS-Vistek for future applications.

Further information about CompControl:

CompControl IT-Service und Vertriebs GmbH (www.compcontrol.de), headquartered in Gersfeld (Rhön) near Fulda, has been planning, developing and implementing IT infrastructures and solutions for companies in the electronics manufacturing sector for over 20 years. The company has particular expertise in the field of integrated warehouse, logistics and traceability solutions with a focus on the production of electronic assemblies. CompControl's customers come from the automotive, safety and medical technology industries and everywhere where quality level one applies.

CompControl IT-Service und Vertriebs GmbH

Schachen 77a

36129 Gersfeld (Rhön)

Tel.: +49 6654 9180820

Fax: +49 6654 8663

www.compcontrol.de